TecnoFruit

Professional collection

Tecnofruit CF-105 Levelling

Tecnofruit CF 105 Levelling is placed alongside the CF 105 to meet the needs

of fruit farmers operating in hilly areas.

of fruit farmers operating in hilly areas.

Tecnofruit CF 105 Levelling is equipped

with a leveling system that keeps the machine in the optimal position in order

to guarantee correct and delicate fruit filling. The balancing of the machine

along the two axes (longitudinal and lateral) is performed by a front piston,

two pistons for the simultaneous lifting of the rear part and two pistons for

the independent side movement of the machine.

with a leveling system that keeps the machine in the optimal position in order

to guarantee correct and delicate fruit filling. The balancing of the machine

along the two axes (longitudinal and lateral) is performed by a front piston,

two pistons for the simultaneous lifting of the rear part and two pistons for

the independent side movement of the machine.

The balancing control can be

manual (electro-hydraulic) or automatic .

manual (electro-hydraulic) or automatic .

An acoustic warnings system signals to the operator the correct positioning

of the machine in order to guarantee the optimal safety operation.

Tecnofruit CF 105 Levelling is the proof that Frumaco Europe has developed and built the

ideal machine for hilly areas where the most suitable fruit growing areas are

often located.

ideal machine for hilly areas where the most suitable fruit growing areas are

often located.

technical data

| Engine | Kubota 3 cyl |

| Type | Diesel 18.5 Kw/ 24,8 hp |

| Front wheels | 26x12.00-12” 8 pr |

| Rear wheels | 26x12.00-12” 8 pr |

| Service brake | - |

| Emergency brake/Parking brake | Hydraulic negative |

| Diesel tank capacity | lt 40 |

| Hydraulic oil tank capacity | lt 90 |

| Aux power | 12 V – 15 A |

| Speed | 0-7 km/h |

| Speed range | 2 + 2 con/mit inversor |

| Transmission | Hydrostatic |

| Steering control | Joystick |

| Trazione | 4WD |

| Massimo livellamento laterale | 20% |

| Massimo livellamento longitudinale | 20% |

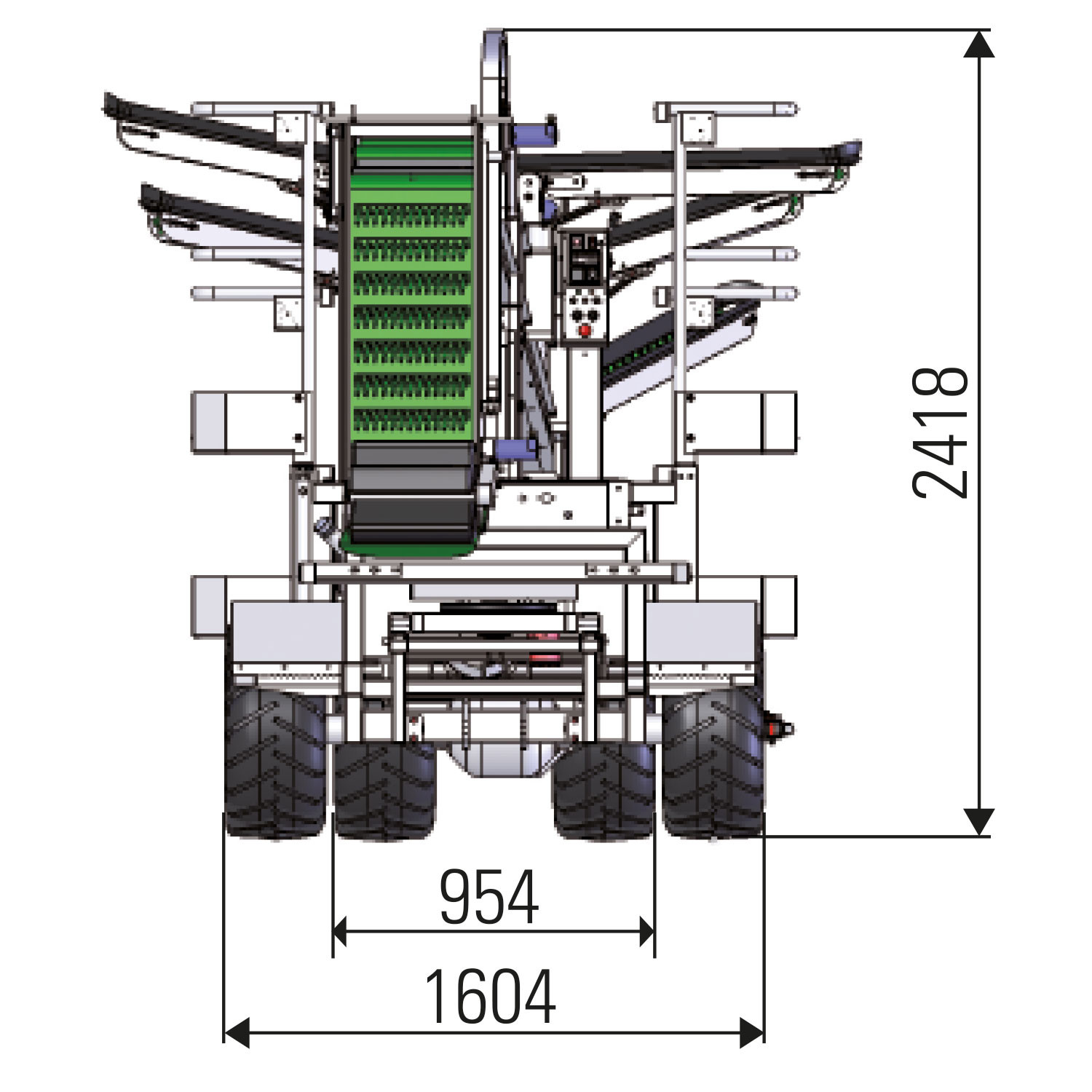

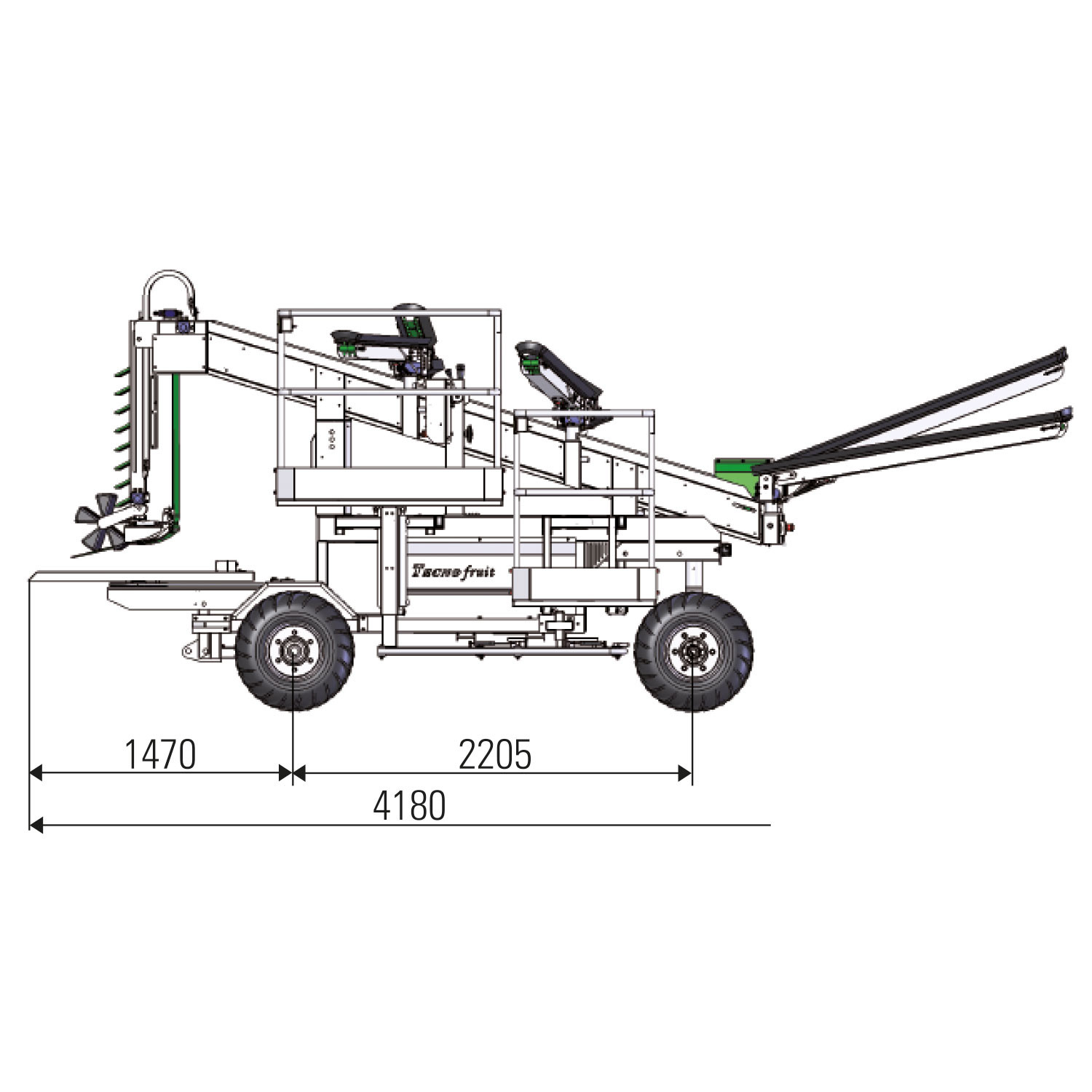

| Lenght (without bins trailer) | mm 4180 |

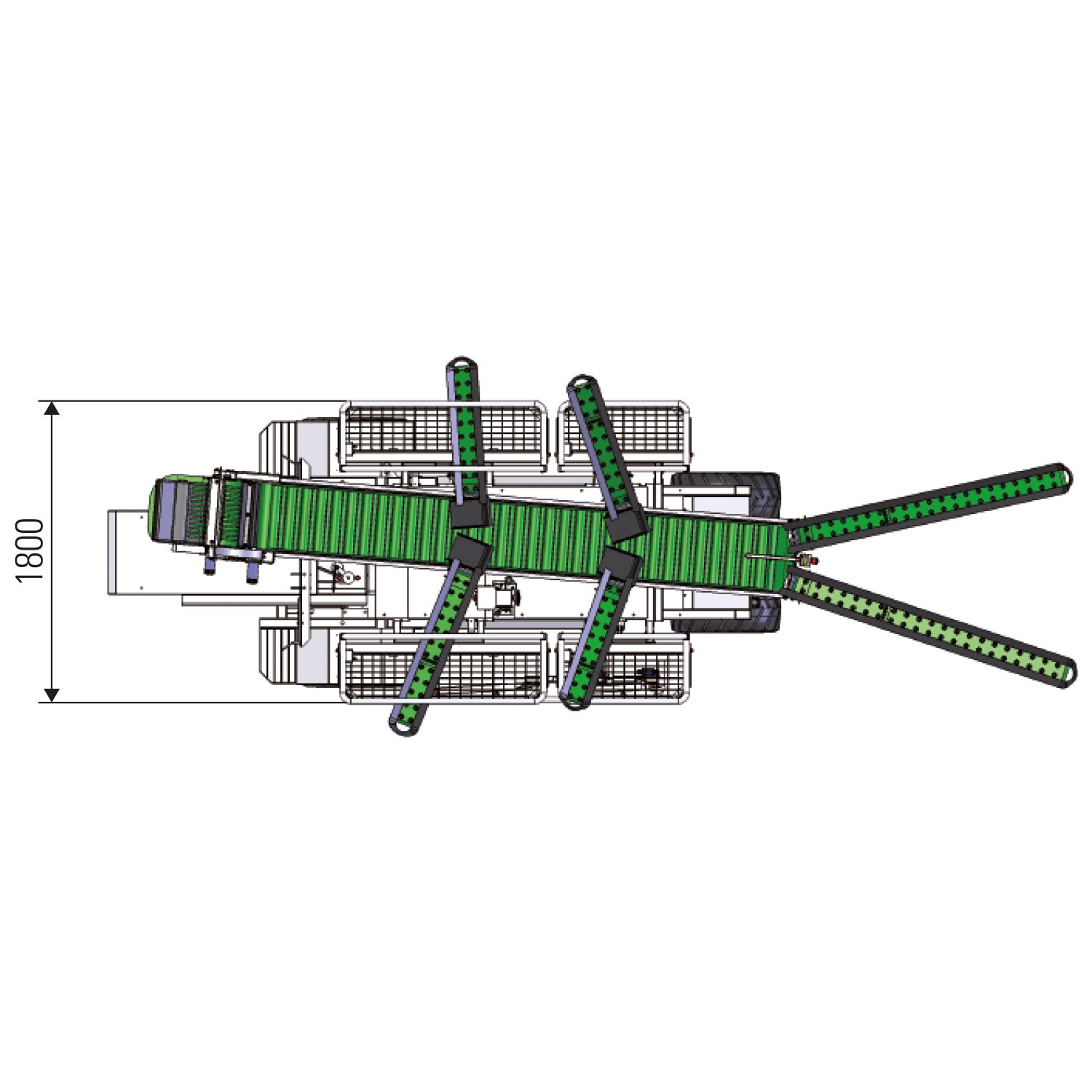

| Width (min/max) | mm 1800 / 3000 |

| Height (min/max) | mm 2418 / 2910 |

| Wheel base | mm 2205 |

| Ground clearance | mm 170 |

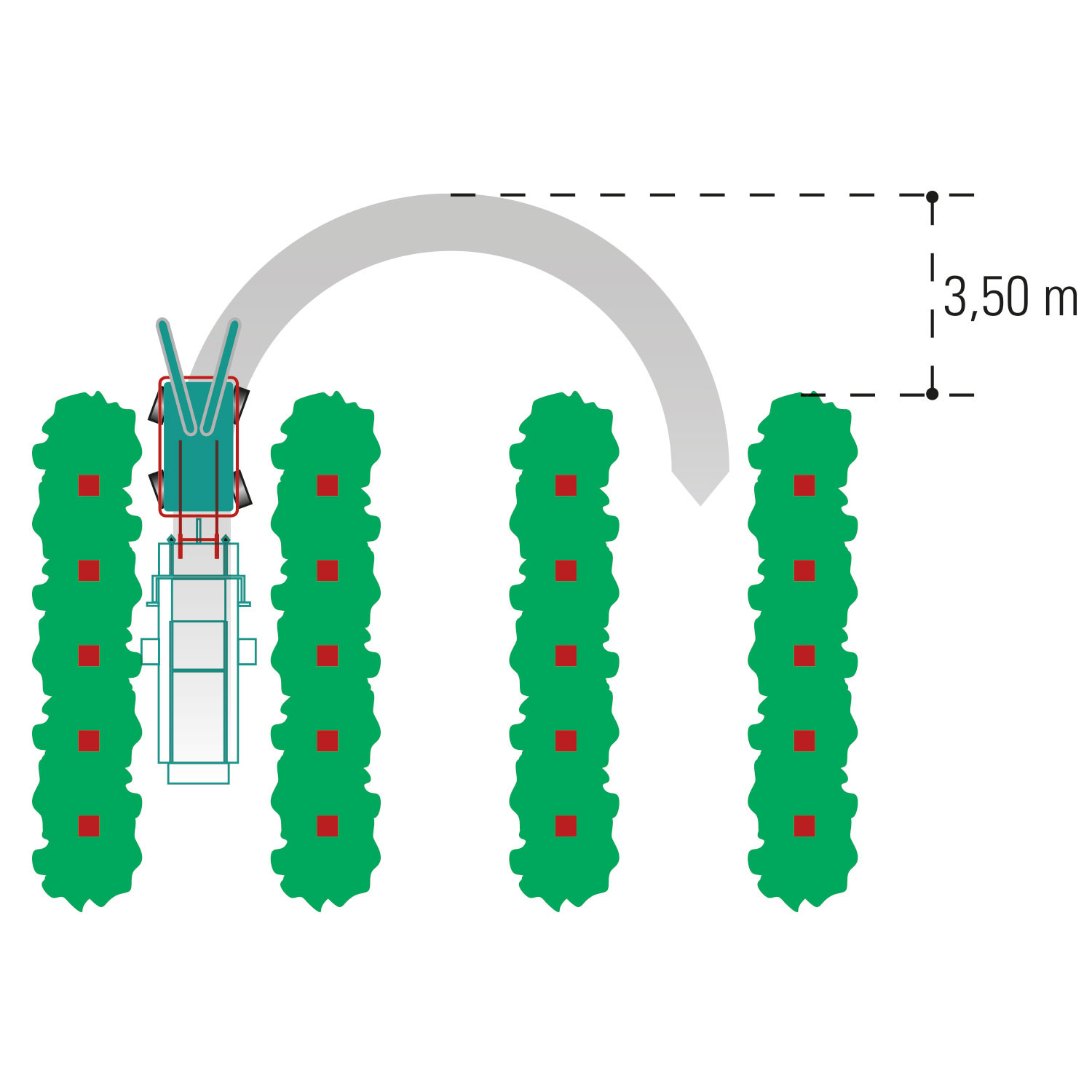

| Tourning radius | m 3,80 |

| Weight | kg 2310 |

O=Optional - nd=Not available - S=Standard

| 2 side platforms 1,25x0,36 m and 2 side platforms 0,80x0,36 m | S |

| Horizontal and vertical Hydraulic adjustment of rear platforms | S |

| Horizontal hydraulic adjustment of front platforms | S |

| Remote control of platforms (433Mhz) | S |

| Automatic bins trailer | O |

| Bins trailer with 4 wheels with bins caliper brake | O |

| 4 side picking belts | S |

| 6 side picking belts | O |

| Central conveyor belt | O |

| 4 wheel drive | S |

| Ultrasound-based automatic steering system | S |

| Hydraulic steering with Joystick | S |

| Additional Joystick | O |

| Industry fruit container | O |

| Front draw bar | O |

| 480 lt external air compressor | O |

| Pneumatic shears and/or pneumatic chainsaw | O |

| Lights kit and service brake | - |

| Negative parking and emergency brake with automatic operation | S |

| Hail net platform width 1,80 - 3,30 m; H=2,95 m; Depth 1,50 m | O |

| Work lights | O |

| Lateral and longitudinal leveling system | S |

| Unloading of full bins on the ground and on the trailer | S |

| Wooden guide profiles for turntable for plastic bins | O |

| Low filler (for low anti-hail systems) including tires 23.00 - 10.50 - 12” | O |

O=Optional - nd=Not available - S=Standard

Tecnofruit CF-105 Levelling

Tecnofruit CF-105 Levelling

Tecnofruit CF-105 Levelling

Tecnofruit CF-105 Levelling

Tecnofruit CF-105 Levelling

Tecnofruit CF-105 Levelling